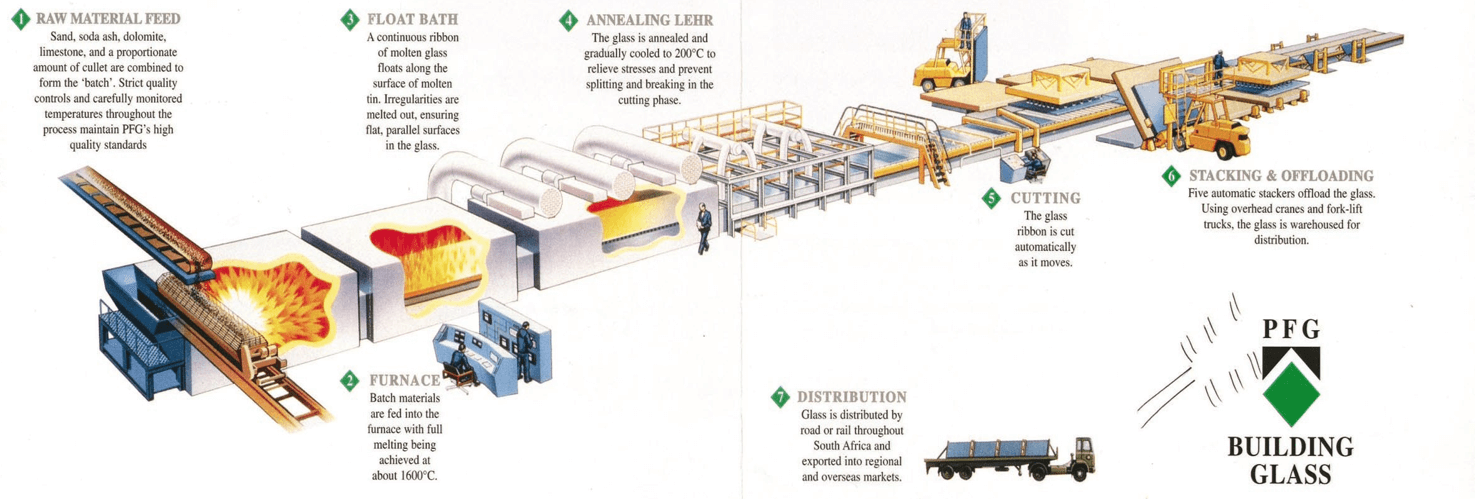

PFG's float lines are among the most advanced of their kind in the world

PFG produces 260,000 tons of quality float glass a year, for supply to customers in the building and automotive sectors across five continents. Our customers include processors, merchants and distributors of glass, furniture manufacturers, appliance manufacturers and aluminium fabricators, as well as producers of automotive glass products to global OEM quality standards.